Flex Eyes 3D

The complete location information of bulk parts can be identified and measured precisely with using 3D factors within cycle time of few seconds:

New Flexeyes 3D sensor’s function. flexible design for automatic line.

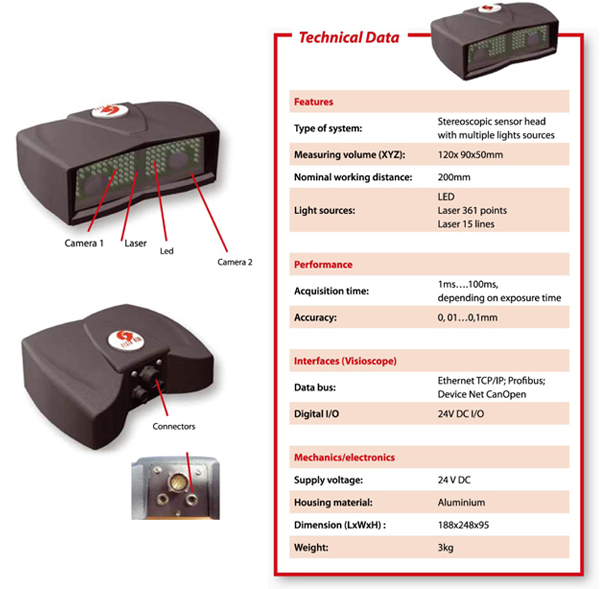

Demands for realizing a flexible and powerful software and hardware solution to apply from component measurements of current automation line to other component measurements is rising. Visio Nerf developed a new sensor combining many other products among its company. The new sensor can measure location or instrumentation(dimension measuring, shape or location defects). Thanks to Visio Nerf’s patented technology, Flexeyes3D sensor can inspect even at an abnormal form spreaded into a complete shape and a broad scope. Combination among LED lights and laser sources more than one provides flexibility, diversity and high-accuracy of sensor.

Product description

Flexeyes3D is the stereo sensor of high accuracy(max 0.01mm) which enables to observe 120x90x50mm sized entities. Integrated light sources block off the peripheral lights influence. Factory calibration makes it possible of rapid realization and simple maintenance. Data provided from Flexeyes3D can be easily processed in visionscope4 controller regardless of Eyeberg technology. Combination between CAD model and Flexeyes3D that exists in a new Eyesberg interface exceeds the limit of robot/vision process.

Three image processing technology to meet customer’s requirements

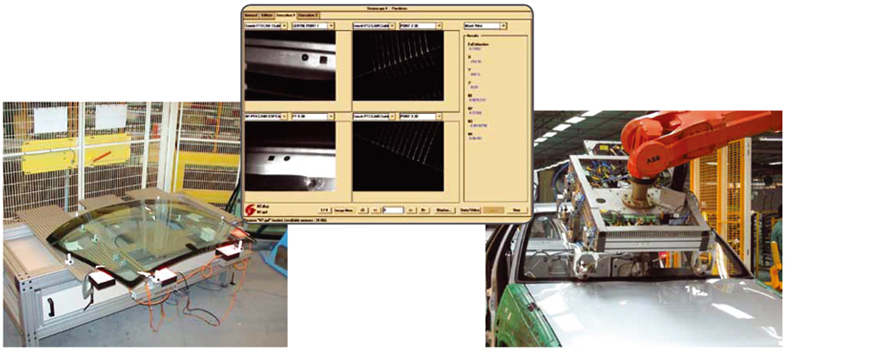

Searching the virtual edge by laser line transform

Application: glass installation automatically with use of robots

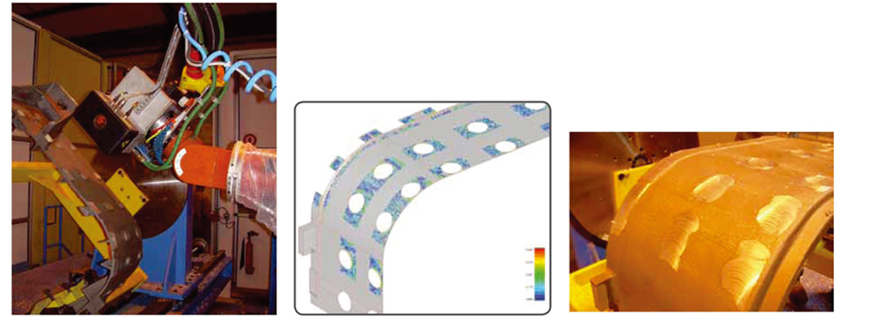

Location measuring of complex and curved surface through multi-point analysis(approx 350 points per image capture)

Application: after comparison with CAD files, location movement to the one before processing

Contrast measurement(diameter, transform into ellipse, location, direction etc.) by LED lights

Application: quality control after drilling

Strength

- high accuracy

- all-in-one sensor

- acquisition speed

- max 6 sensors can be connected to a same vision controller

- high tolerance about the surrounded light

- various lights sources

Benefits

- rapid realization

- no need of special machine device

- various tool

- application of products with complex surface(complex curved surface)