Cirrus

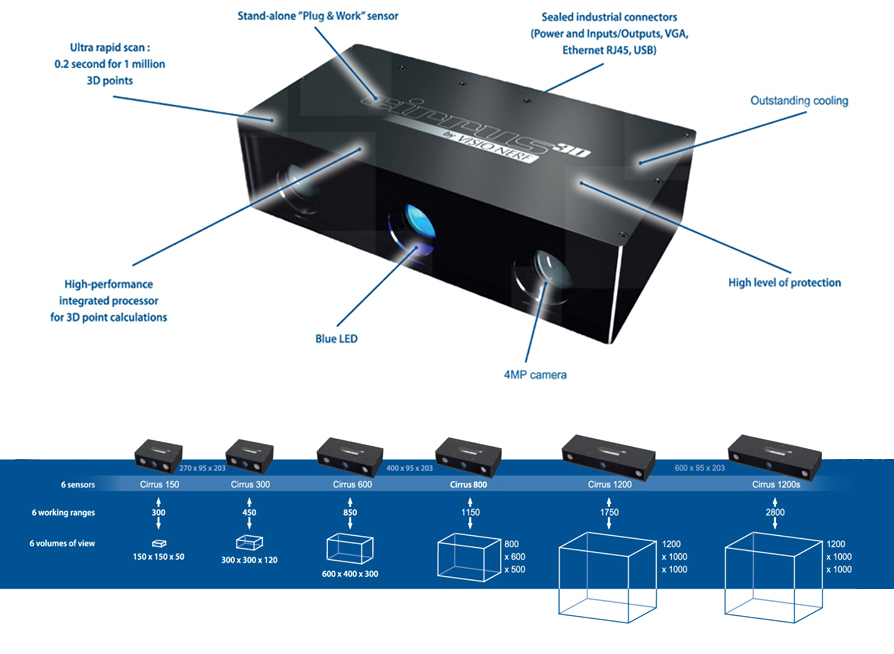

This new VISIO NERF’s 3D sensor has no need of a special development,

but is easily installed and integrated within industiral process.

VISIO NERF 3D sensor guarantees of high reliability and firmness because it is developed as industrial products not to be affected by severe environment (dust, filth or natural lighting). The optimized solution to wide applications such as assembling, measuring, identifying and Bin Picking would be offered.

Features

- Top-of-the-line scanner

- Stand-alone tyle, “Plug&Work” available due to pre-calibration by the time of releasing (built into computers) high resolution image

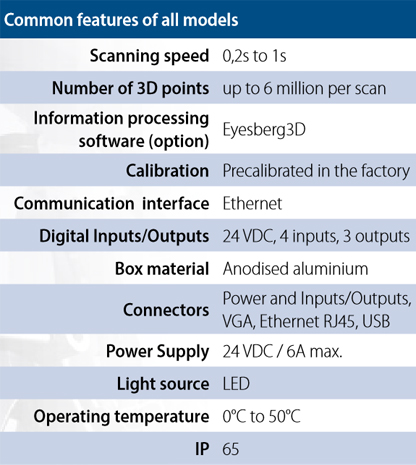

- superhigh speed scan : 1million 3D points per 0.2 second

- Comparison between Point cloud and CAD file(option)

- application of fixed way and non-fixed way(bin picking, localization, identification and measurement)

- Structured light illumination (Blue LED)

Benefits

- reasonable price and superior performance

- non-influenced by perimetric lights

- high stability due to replacement with verified technology, LED

- operating by building in robots

- simplification of communication protocol

- setting parameters with Eyesberg3D vision application on options

- direct programming with web server or screen/mouse

Software(Option)

Vision Nerf’s Eyesberg3D software solution makes the following application happened.

- measurements of each part

- Bin Picking with robots

- compensation of robot routes

- 3D measurements of all products regardless of size

- identification of dissimilar components

Eyeberg3D software solution is included in CIRRUS3D’s embedded computers when releasing so that can be used as soon as plugging in.