IT+Robotics

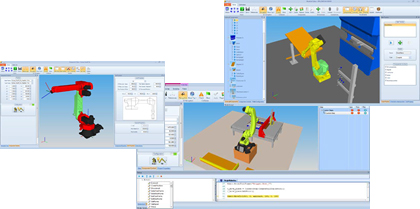

3D Simulation

WorkCellSimulator is a 3D simulator for

the off-line programming of workcells and machines with several axis.

IT+Robotics specializes in developing quality

control systems that can autonomously identify any defects in the

products coming from a production line.

Robot Guidance

Smart Pick 3D is the software for the visual identification of

the position and location of items within the production line.

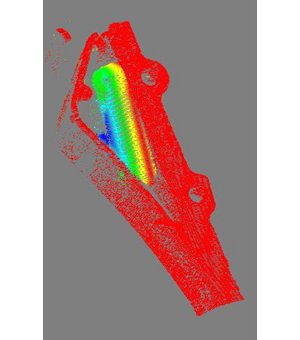

Thermobot Project

ThermoBot-Autonomous robotics system for

thermo-graphic detection of cracks.

3D Scan / Random Bin Picking / Inspection

WORKCELL SIMULATOR

This is perfect and adequate software to off-line robot programming.

1. Create your work cell

- editing the component

- building component’s database

- editing work cell

- creating work cell

2. Simulate it:

- defining Simulator component motions and automatically producing robot’s routes

3. Bring it to real world

- convert Robot Code Complier simulation into work robot code

Autonomous

Flexibility increasement of producing work cell by permitting a reduction of setting time and a reduction of arrangement size into single size

- work cell programming interacts with easy-to-use user interface working off-line

- using the latest motion planning engine and all routes are automatically figured

- simulator can be extended with use of task planning algorithm in accordance with specific simulated process

Application

Bending Process

Palletization

CNS Simulation

Visual Quality Inspection

… And More!

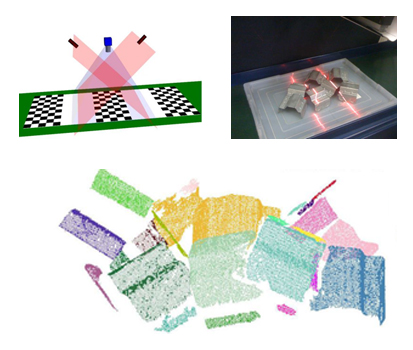

- Rigidity : plan, reflective and 3D objects arranged with the random method

- accuracy : choosing the appropriate optics sensor to accuracy requirements

- expandability : multiple fixed vision system equipped with linear axis or robot controller

- flexibility : possibility of choosing the number of cameras, lights, and location of laser units

- reliability : automatic program correction for assuring high-accuracy

- economic feasibility : industrial camera. stand optics and independent laser projector

- easy-to-use : off-line programming of new products with a complete autonomy

- integrity : compatibility with all robots and PLC for guaranteeing the best adaptability to producing line

- effect : decision making of emptying the bin and inference of laser alarm device for anti-collision

- user design : processing the special cases about specific algorithms and GUIs

| VERSION | CONTECT | PRODUCTS | TECHNOLOGY | CONFIGURATION |

|---|---|---|---|---|

| Profile | Belt | All | Cameras | Cad self-learning |

| Shape | Bin | Levels | Cameras | CAD 2D |

| Solid | Bin | All | 3D Sensor | CAD self-learning |

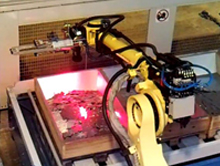

Smart Pick3D

Fast and efficient robot guidance for random bin-picking.

- scrapping paper when recognizing randomly positioned objects into the robot manual Bin within Random bin-picking and finding out the exact location

Advantages:

- easy-to-integrate with the existing work process

- simple manufacturing switch

- more compact that solution based on conveyor belt

- reduction of cycle time(max 5 seconds)

= More flexibility

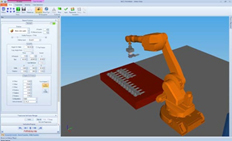

Smart Pick 3D Profile

- Standard camera

- Conveyor belt

- Very fast (< 0.5 s)

Smart Pick 3D Shape

- Standard camera

- Bin

- High reflective objects

Smart Pick 3D Solid

- 3D sensor

- Bin

- Complex geometry

Common features:

- correction of automation adjustment

- easy to use GUI for products composition

- operating with all robots

- completely emptying Bin

- High-performance : 100% production management

- accuracy : choosing the appropriate optics sensor to accuracy requirements

- expandability : multiple fixed vision system equipped with linear axis or robot controller

- flexibility : integrated 2D and 3D system

- reliability : automation program correction for assuring repeatability

- economic feasibility : industrial camera. stand optics and independent laser projector

- easy-to-use : off-line programming of new products with a complete autonomy

- optimization : auto-computing of optimum control period of robot system

- integrity : compatibility with all robots and PLC for guaranteeing the best adaptability to producing line

- user design : processing the special cases about specific algorithms and GUIs

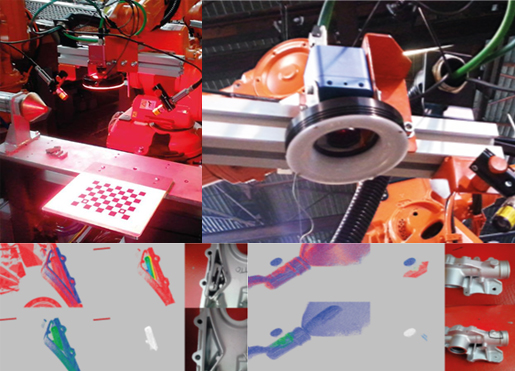

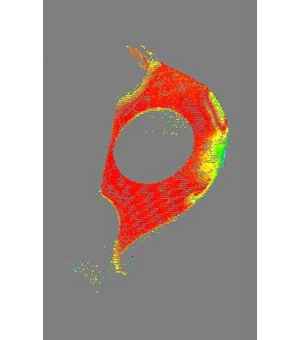

Smart Check3D

High performance quality control integrated into the production line.

- automatic eye inspection

- combination among single sensor, 3Division and 2Division

- all visualization inspection check can be done even if focusing on the integrity test

- 2 ways of configuration

- Conveyor belt: to maximize cycle time

- vision system on robots : to maximize the flexibility

- high performance quality management integrated into the production line

- simple programming

- programming can be operated at off-line

Completeness

3D Measurement

Inclusions

Surface inspection