Bin Picking

♦ BIN PICKING ?

The monotonous tasks such as unloading an object from the BIN to deploy to the desired equipment and/or arranging the unsorted parts in a Bulk require a lot of labor. Moreover, the most of tasks may have many risk factors.

In many years, BIN-PICKING Robots have been performing not only those monotonous but also dangerous tasks. The attention on BIN PICKING has been increasing throughout the production or logistics automatic process, even though its system may still have to discover the relative application cases.

BIN PICKING has been developed tremendously, but still it has limited barriers in many areas. In the BIN PICKING area, the RANDOM BIN PICKING may be defined as the best performance which has not been completely conquered, but it has a groundbreaking development. The Robots are discovering the way in the unknown world thanks to the advanced Vision Technology, Software and Gripper solution.

If so, why is the RANDOM BIN PICKING so difficult? It is all about the ‘Precision’. The repeatability of Robot has been well recognized whereas Precision of the RANDOM BIN PICKING has been facing difficulty. The Robot must precisely detect the location of parts which are changing its location and direction by each picking procedure. To execute the RANDOM BIN PICKING, the role of robot, Machine Vision, Software, Computing Technology for analyzing a huge DATA in a real time and Gripper solution for picking an object must be balanced. It is hard to execute, but not impossible.

Dasan NewTech provides the RANDOM BIN PICKING that is an ideal Robot Guidance solution. Its advanced Vision system allows picking a randomly located object from the BULK or on the Conveyor Belt. Furthermore, 3D Machine Vision applied to its system offers a remarkable ‘diversity’ that may allow various types of parts to be applied to the existing Automation system and Automatic lines. In other words, it can be customized in development not just for a singular type as limitation, but also for a various equipment system through product code and programming.

Dasan NewTech’s BIN PICKING SYSTEM is compatible with all brands of Robots and PLC with an ease of application to the product line.

However, during the development, it should be cautioned of robustness and continuity of function. Even though there is remarkable Unique Algorithms for gripping without missing a part, the Gripper must have the function of Anti-Collision System and be customized with consideration of desired products and applications.

Even though the desired product can vary, the various Technologies are required regards of Hardware and Software, Dasan NewTech has a solution of Robot Guidance for a various product types by co-operating with Global partners and provides the best outcome and the cost efficiency through these solutions.

♦ 3 Main Items of BIN PICKING

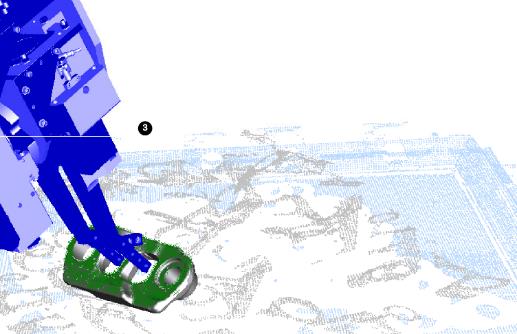

- Digitalization – The TOOL connected to a 3D sensor can digitalize actual work area to 3D CLUSTER

- Location Tracking – From the 3D measurements by using calculation algorithm. To find out the location of the best products which are able to be PICKED-UP. For an accurate, and correct grip, the overlap areas with other parts should be SIMULATED first of overlap with other parts in the virtual 3D workspace.

- GRIPPING – BIN PICKING PROGRAM provides the position information (THREE TRANSLATION COMPONENTS) and direction information (THREE ROTATION COMPONENTS) of the parts for the gripping by the robot. It shows the information of pre-selected products that are possible to grip through a number of gripping strategies that have been built before to the robot. Meanwhile, robot program will select one of the grip strategies according to its own constraints based on considering the accessibility or independence (independent position).